| Certification: | ISO |

|---|---|

| Installation Method: |

Vertical |

| Operation Type: |

Automatic |

Smoke Clearance Device of Wet Scrubber, Find Details and Price about Boiler Parts Boiler Accessories from Smoke Clearance Device of Wet Scrubber

| Certification: | ISO |

|---|---|

| Installation Method: |

Vertical |

| Operation Type: |

Automatic |

Smoke Clearance Device of Wet Scrubber, Find Details and Price about Boiler Parts Boiler Accessories from Smoke Clearance Device of Wet Scrubber

DMC PULSE BAG DUST COLLECTOR WORKING PRINCIPLE

Dust smoke go into this collector from its middle part,some heavy dust due to its weight will fall down to bottom dust hopper, other light dust will go into filter of bag and stick at outside of bags, clean smoke will go through the bags and come out from top of this collector.Due to dust sticked on bags continously adding, the resistance will geting higher,when it reaches1.0-1.2kpa.pulase controller will automatically start ,pulase valve will open, and spray to all bags ,and make bags coming big suddenly,removing the dust sticked on bags, and these dust will fall down to bottom dust hopper and then drain out of the collector through discharge valve.

| Name | DMC32 | DMC48 | DMC64 | DMC80 | DMC96 | DMC112 | DMC128 |

| Filting area(m2) | 24 | 36 | 48 | 60 | 72 | 84 | 96 |

| Q of bags | 32 | 48 | 64 | 80 | 96 | 112 | 128 |

| Bag size(mm) | ø120X2000 | ||||||

| Pressure lose Pa | 1200 | ||||||

| Dust remve efficiency ‰ | 990-999 | ||||||

| Inlet smoke dust content g/m3 | ≤200 | ||||||

| Filting smoke speed m/min | 1-2 | ||||||

| Capacity m3/h | 1500-2400 | 2500-3500 | 3500-4500 | 4500-5500 | 5000-6500 | 6500-8500 | 8500-9200 |

| Pulase valve size | 1″ | 1″ | 1″ | 1″ | 1″ | 1″ | 1″ |

| Pulase valve quantity | 4 | 6 | 8 | 10 | 12 | 14 | 16 |

| Over size(mm) | 1440X760X4000 | 1440X1100X4000 | 1440X1440X4000 | 1440X1780X4200 | 1440X2120X4200 | 1440X2460X4200 | 1440X2800X4500 |

| Weight(kg) | 1350 | 1620 | 1850 | 2360 | 2800 | 3200 | 3600 |

| Supply air pressure Mpa | 0.4-0.6 | ||||||

| Fan power kw | 1.5 | 2.2 | 3 | 5.5 | 7.5 | 7.5 | 7.5 |

| Compressed air consumption m3/min | 0.13 | 0.17 | 0.21 | 0.25 | 0.3 | 0.34 | 0.42 |

| Suitale for Boiler | 1T | 1T | 1T | 1T | 2T | 2T | 3T |

| Name | MC100 | MC120 | MC150 | MC180 | MC200 | MC240 | MC300 | MC360 | MC420 | MC490 | MC560 |

| Filting area(m2) | 100 | 120 | 150 | 180 | 200 | 240 | 300 | 360 | 420 | 490 | 560 |

| Q of bags | 100 | 120 | 150 | 180 | 200 | 240 | 300 | 360 | 420 | 490 | 560 |

| Bag size(mm) | ø130X2450 | ||||||||||

| Pressure lose Pa | 1200 | ||||||||||

| Dust remve efficiency ‰ | 990-999 | ||||||||||

| Inlet smoke dust content g/m3 | ≤100 | ||||||||||

| Filting smoke speed m/min | 1-2 | ||||||||||

| Capacity m3/h | 7800-10200 | 10200-12000 | 11700-15300 | 15000-18300 | 17000-20500 | 19000-24500 | 25000-28800 | 29000-35000 | 35200-40500 | 41000-47500 | 47800-54000 |

| Pulase valve size | 1.5″ | 1.5″ | 1.5″ | 1.5″ | 1.5″ | 1.5″ | 1.5″ | 1.5″ | 1.5″ | 1.5″ | 1.5″ |

| Pulase valve quantity | 10 | 10 | 10 | 15 | 20 | 20 | 25 | 30 | 30 | 35 | 40 |

| Over size(mm) | 2150X2150X5500 | 2150X2270X5500 | 3170X2150X5500 | 3170X2270X5800 | 4190X2150X5800 | 4190X2870X5800 | 5210X2870X6000 | 6230X2870X6000 | 6230X3372X6000 | 7250X3372X6000 | 8270X3372X6000 |

| Weight(kg) | 3600 | 4320 | 5400 | 6480 | 7200 | 8450 | 10600 | 12400 | 14500 | 16800 | 19500 |

| Supply air pressure Mpa | 0.4-0.6 | ||||||||||

| Insulation area(m2) | 35 | 38 | 42 | 48 | 55 | 65 | 77 | 88 | 98 | 110 | 122 |

| Compressed air consumption m3/min | 0.55 | 0.65 | 0.85 | 1.01 | 1.2 | 1.37 | 1.59 | 1.73 | 2.08 | 2.1 | 2.3 |

| Suitale for Boiler | 2T | 4T | 5T | 6T | 7T | 8T | 9T | 10T | 12T | 15T | 20T |

Boiler FAQs

Q: What different types of boilers are available?

DZL type steam/hot water boiler

SZL type steam /hot water boiler

SHL type steam /hot water boiler

WNS type steam /hot water boiler

SZS type steam /hot water boiler

SZW type steam /hot water boiler

CFB type steam boiler

YLW type thermal oil boiler/heater

YYL(W) type thermal oil boiler/heater

WNS type thermal oil boiler/heater

SZS type thermal oil boiler/heater

SZW type thermal oil boiler/heater

Waste heat recovery boiler

Steam generator

Q: What is a fire tube steam boiler?

A fire tube steam boiler is a boiler where the combustion gases from the burner are channeled through tubes that are surrounded by the fluid to be heated. The boiler body is the pressure vessel and contains the fluid. In most cases, this fluid is water that will circulate for heating purposes or become steam for use in processing.

Each set of tubes through which the combustion gas passes, before making a turn, is considered a “step”. Consequently, a three-step boiler will have three sets of pipes with the outlet located at the rear of the boiler.

Q: What’s advantages of our boiler?

Wide Range of Fuel Type

Applicable for a various of light oil, furnace oil, natural gas, LNG, biogas, coke gas, methanol, biodiesel, etc.

High Thermal Efficiency

New and unique design with high thermal efficiency, which save running cost of buyer

Unique Control System

Unique three-elements control system with PID unit covered PLC, inverters, and HMI to reach high level automatic running of boiler

Q: What is the turndown ratio of our boilers?

our boilers feature turndown ratios of 5:1, means the boiler’s minimum operating load is 20% of the boiler’s full capacity (100% capacity)

Q: How do I choose the right boiler?

Firstly, check the actual steam pressure and consumption required at present, and discuss with management there are extra steam required or not in next five years.

Secondly, confirm the boiler fuel type, then we will provide you an optimal boiler that take all factors in consideration.

Q: How long does an industrial steam boiler last?

The normal service life of a steam boiler is 10 to 20 years, provided that proper care and maintenance routines are applied to the feedwater and interior of the boiler.

When considering steam boiler replacement, the three most important aspects to consider are safety, economy and changing requirements to perform the function for which it is operating.

Q: What services for industrial boilers does our offer?

we offers its customers the following services for industrial steam boiler, thermal oil boiler and waste heat recovery boilers and steam generators:

Customized boiler designs.

Super quality boiler product

Installation and commissioning service

Operators training service

Lifetime maintenance service.

Q: What safety features do steam boiler have?

Boiler shutdown protection due to water level low

Boiler shutdown protection due to continuous water level low

Boiler shutdown protection due to steam pressure high

Safety valve over pressure protection.

Automatic FWP on / off

Q: What is the lead time of our boiler

The subject boiler will be delivered within 60 -90 days based on boiler capacity

Q: What primary components for boilers are there?

The most common accessories are:

Burner

Economizer and condenser

Feed water pump

Thermal deaerator (if necessary)

Chimney

Control panel

Instrument gauges and valves

we supplies all types of complementary equipment for industrial steam boilers, and designs new equipment and tools if they are necessary for the final installation to meet its clients’ expectations.

Q: What are the optional items of boiler for buyer choose from

Steam and feed water flow meter

Periodic blowdown expander (if necessary)

Continuous blowdown expander (if necessary)

Thermal deaerator (if necessary)

Q: What is the supply scope of boiler arranged by buyer

Whole civil works engineering by our design drawing

All connecting piping (steam, feed water piping)

All connecting cables (motor cables, single cables, main power supply cable)

Some connecting valves from feed water pump point

Chimney manufacture on site by our design drawing

Balance flue gas ducting manufacture on site by our design drawing

Thermal deaerator

Q: How does boiler warranty work?

The subject boiler is covered by a twelve months warranty against mechanical and/ or factory defects from date of test-run or 18 months from the date of shipment whichever comes earlier.

we shall repair or replace the components, parts or accessories covered by warranty that had become inoperative within the warranty period but not covered caused by faulty operation from the buyer.

we will provide lifetime service for boiler with cost when its warranty expired.

Q: Who will be fitting my new boiler?

Simply, a local professional boiler installing company will install the subject boiler under our engineer’s instruction and supervision

Q: How long will my installation & commissioning take?

Typically, the whole installation & commissioning work may take 1-4 months based on the subject boiler capacity.

Q: How often should I maintain my boiler?

Overhaul inspection and maintenance: 1-3 month

we will provide detail brochure regarding how and when to do maintenance work during boiler running.

| Business Type: | Manufacturer/Factory, Trading Company | |

| Main Products: | Steam Boiler , Boiler , Coal/Biomass/Oil/Gas Fired Boilers | |

| Registered Capital: | 10000000 RMB | |

| Plant Area: | >2000 square meters | |

| Management System Certification: | ISO 9001, ISO 9000, ISO 20000, QC 080000, GMP, BSCI, BRC, ANSI/ESD, GAP,QSR | |

| Average Lead Time: | Peak Season Lead Time: 1-3 months Off Season Lead Time: one month |

Qingdao Hammer Industries Co., Ltd is engaged in manufacturing and exporting industrial boiler for more than 20years. Such as coal/biomass/oil/gas steam boilers, hot water boilers and thermal oil heaters. Based on such many years experience for manufacturing boilers, Our engineers collected more questions from kinds of our valved domestic and oversea clients, and they improve our boilers day by day. So now Our boilers and accessories can suitable all kind of industrial boilers. Our boiler manufacturer have own ISO9001 qualification system. What′s more, tehy also got SGS certificate, and CE certificate, even ASME certificate. Our boiler lifespan can reach 20 years. We are dedicated to global market. Nowadays, we have exported boilers to more than twenty countries, such as Europe, Middle East, Southeast Asia, and Africa. During the past years, our company is developing quickly and stably at the annual growth speed of 100%. We adhere to the management principles of quot&quality first, customer first and credit-based” Since the establishment of the company and always do our best to satisfy potential needs of our customers.

Qingdao Hammer Industries Co., Ltd is sincerely willing to cooperate with enterprises from all over the world in order to realize a win-win situation since the trend of economic globalization has developed with an irresistible force.

Qingdao Hammer Industries Co., Ltd is engaged in manufacturing and exporting industrial boiler for more than 20years. Such as coal/biomass/oil/gas steam boilers, hot water boilers and thermal oil heaters. Based on such many years experience for manufacturing boilers, Our engineers collected more questions from kinds of our valved domestic and oversea clients, and they improve our boilers day by day. So now Our boilers and accessories can suitable all kind of industrial boilers. Our boiler manufacturer have own ISO9001 qualification system. What′s more, tehy also got SGS certificate, and CE certificate, even ASME certificate. Our boiler lifespan can reach 20 years. We are dedicated to global market. Nowadays, we have exported boilers to more than twenty countries, such as Europe, Middle East, Southeast Asia, and Africa. During the past years, our company is developing quickly and stably at the annual growth speed of 100%. We adhere to the management principles of quot&quality first, customer first and credit-based” Since the establishment of the company and always do our best to satisfy potential needs of our customers.

Qingdao Hammer Industries Co., Ltd is sincerely willing to cooperate with enterprises from all over the world in order to realize a win-win situation since the trend of economic globalization has developed with an irresistible force.

| International Commercial Terms(Incoterms): | FOB, CFR, CIF, DAT, FAS, DDP, DAP, CIP, CPT, FCA, EXW |

|---|---|

| Terms of Payment: | LC, T/T, D/P, PayPal, Western Union, Small-amount payment, Money Gram |

| Average Lead Time: | Peak Season Lead Time: 1-3 months, Off Season Lead Time: one month |

| Number of Foreign Trading Staff: | 1~3 People |

| Export Year: | 2018-08-01 |

| Export Percentage: | 41%~50% |

| Main Markets: | South America, Eastern Europe, Southeast Asia, Africa, Mid East |

| Nearest Port: | QINGDAO |

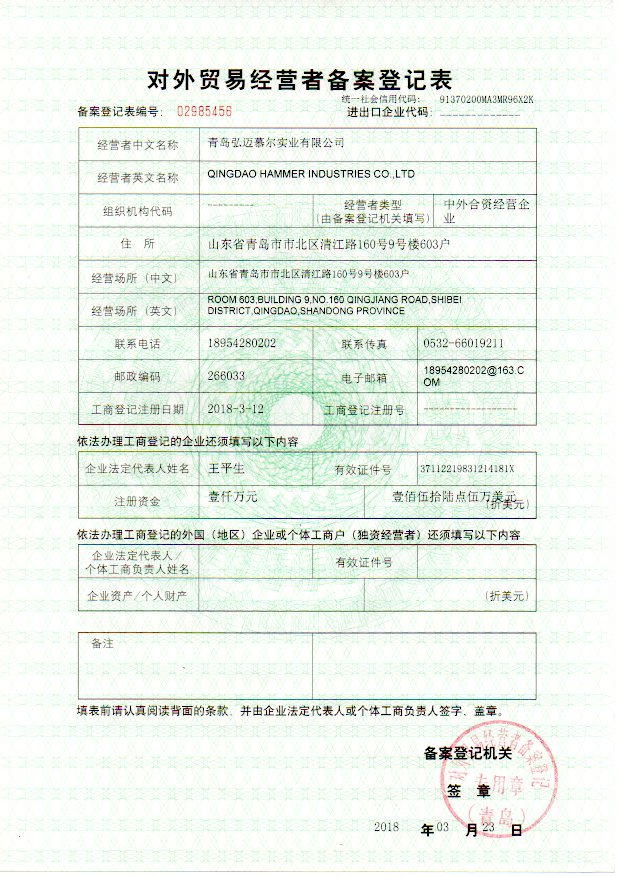

| Import & Export Mode: | Have Own Export License

Export License Number: 02985456 Export Company Name: QINGDAO HAMMER INDUSTRIES CO.,LTD |

| Factory Address: | LIAO LAN TOWN ,PINGDU,QINGDAO ,CHINA |

|---|---|

| R&D Capacity: | OEM, ODM, Own Brand() |

| No. of R&D Staff: | 5-10 People |

| No. of Production Lines: | 2 |

| Annual Output Value: | US$2.5 Million – US$5 Million |

| Ever Annual Output of Main Products: | Product Name Units Produced (Previous Year)

boiler 150 Pieces |