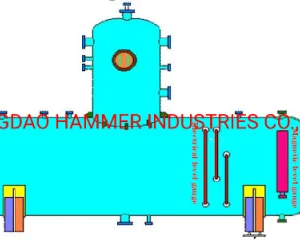

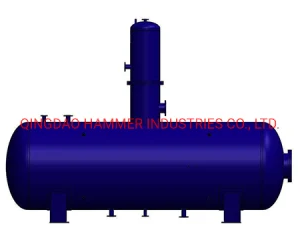

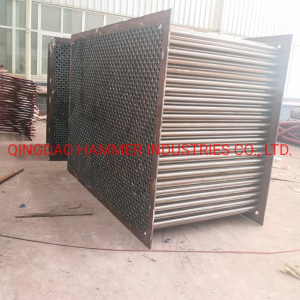

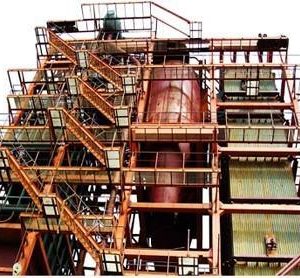

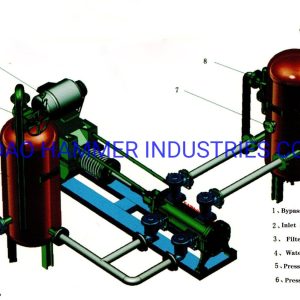

| Function: | Water Boiler, Steam Boilers |

|---|---|

| Fuel: | Waste Heat |

| Installation: | Packaged Boiler |

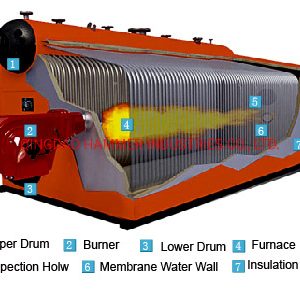

Dzw Reciprocating   Grate Steam Boiler Especially for Wood Chips, Find Details and Price about Steam Boiler Coal Fired from Dzw Reciprocating   Grate Steam Boiler Especially for Wood Chips