| Function: | Water Boiler, Steam Boilers |

|---|---|

| Fuel: | Waste Heat |

| Installation: | Packaged Boiler |

Dzw Reciprocating   Grate Steam Boiler, Find Details and Price about Steam Boiler Coal Fired from Dzw Reciprocating   Grate Steam Boiler

| Function: | Water Boiler, Steam Boilers |

|---|---|

| Fuel: | Waste Heat |

| Installation: | Packaged Boiler |

Dzw Reciprocating   Grate Steam Boiler, Find Details and Price about Steam Boiler Coal Fired from Dzw Reciprocating   Grate Steam Boiler

DZW reciprocating grate steam boiler

This boiler was designed especially for poor coal,solid waste and city waste.

| Boiler Model | DZW1-1.0/1.25-AII | DZW2-1.0/125-AII | DZW4-1.25/1.6-AII | DZW6-1.25/1.6-AII | ||

| Rated Evaporation Capacity | t/h | 1 | 2 | 4 | 6 | |

| Operation Pressure | Mpa | 1.0/1.25 | 1.0/1.25 | 1.25/1.6 | 1.25/1.6 | |

| Steam Temperature | ºC | 183/194 | 183/194 | 194/204 | 194/204 | |

| Water-inlet Temperature | ºC | 20 | 20 | 20 | 20 | |

| Boiler Heating Efficiency | % | ≥81.2 | ≥81.2 | ≥81.3 | ≥81.2 | |

| Area of Stoker | m2 | 2.38 | 4.2 | 5.54 | 7.63 | |

| Coal Available | poror coal,solid waste,city waste,other biomass fuel | |||||

| Blast Fan | Model | GG1-15 L0° | GG2-15 L0° | GG4-15 L0° | GG6-15 L0° | |

| Ventilation | m³/h | 2400-3500 | 2600-4200 | 7000-10000 | 7200-12000 | |

| Wind Pressure | Pa | 1834-1579 | 3138-2550 | 3314-2844 | 3548-2916 | |

| Motor Power | KW | 4 | 5.5 | 11 | 18.5 | |

| Induced Draft Fan | Model | GY1-15 R45° | GY2-15 R45° | GY4-15 R0° | GY6-15 R0° | |

| Ventilation | m3/h | 3800-6800 | 5200-8500 | 11500-16000 | 15765-19320 | |

| Wind Pressure | Pa | 2942-2373 | 3668-3020 | 3805-3510 | 4106-4057 | |

| Motor Power | KW | 7.5 | 11 | 22 | 37 | |

| Dimensions of Biggest Parts for Shipment | M | 5.15×2.04×2.78 | 5.525×2.4×3.28 | 5.95×2.66×3.53 | 6.695×2.8×3.6 | |

| Weight of Biggest Parts for Shipment | T | 16 | 24.4 | 29.8 | 37 | |

Remark: This parameter is just for reference, for exact parameter, subject to our drawings.

Technical advantages

1.Wing flue can cool down smoke in high temperature tube sheet, avoid subcooled boiling, reduce boiler bottom heat load, avoid tube sheet crack, avoid drum deformation.

2.Arch tube plate can Improve tube sheet flexibility, reduce welding seam thermal stress. remove brace and avoid tube sheet crack.

3.Thread tube can enhance heat transfer,reduce drum size,improve flexibility, reduce welding seam thermal stress.

Design characteristics

Soot inertial separation device is set inside boiler and Big volume natural sedimentation chamber is set on the rear arch top. Smoke flow speeds is slow here, some particles in the smoke can be separated out because of gravity. The smoke turns fast at the head of wing flue, and many particles are separated out because of inertia. It lows original emission concentration. The ash in the rear arch can fall on the grate by ash falling hole, then be removed, which decreases secondary pollution. The boiler operates well and turns out that the original emission concentration is less than 2000mg/Nm³. Besides, with the equipped high efficiency dust collector, the boiler emission concentration satisfies national 1-class standard.

The intense radiation furnace arch can form reasonable ‘A’ style fire to prompt the combustion. Water cooling wall forms furnace upon the grate. It is big enough to burn the coal completely. The reasonable arch arrangement ensures flow speed. Meanwhile, the inside thread smoke tube, high efficient burning device, well-designed arches and high quality insulation materials and other characteristics ensure the boiler thermal efficiency is higher than national standard.

| Business Type: | Manufacturer/Factory, Trading Company | |

| Main Products: | Steam Boiler , Boiler , Coal/Biomass/Oil/Gas Fired Boilers | |

| Registered Capital: | 10000000 RMB | |

| Plant Area: | >2000 square meters | |

| Management System Certification: | ISO 9001, ISO 9000, ISO 20000, QC 080000, GMP, BSCI, BRC, ANSI/ESD, GAP,QSR | |

| Average Lead Time: | Peak Season Lead Time: 1-3 months Off Season Lead Time: one month |

Qingdao Hammer Industries Co., Ltd is engaged in manufacturing and exporting industrial boiler for more than 20years. Such as coal/biomass/oil/gas steam boilers, hot water boilers and thermal oil heaters. Based on such many years experience for manufacturing boilers, Our engineers collected more questions from kinds of our valved domestic and oversea clients, and they improve our boilers day by day. So now Our boilers and accessories can suitable all kind of industrial boilers. Our boiler manufacturer have own ISO9001 qualification system. What′s more, tehy also got SGS certificate, and CE certificate, even ASME certificate. Our boiler lifespan can reach 20 years. We are dedicated to global market. Nowadays, we have exported boilers to more than twenty countries, such as Europe, Middle East, Southeast Asia, and Africa. During the past years, our company is developing quickly and stably at the annual growth speed of 100%. We adhere to the management principles of quot&quality first, customer first and credit-based” Since the establishment of the company and always do our best to satisfy potential needs of our customers.

Qingdao Hammer Industries Co., Ltd is sincerely willing to cooperate with enterprises from all over the world in order to realize a win-win situation since the trend of economic globalization has developed with an irresistible force.

Qingdao Hammer Industries Co., Ltd is engaged in manufacturing and exporting industrial boiler for more than 20years. Such as coal/biomass/oil/gas steam boilers, hot water boilers and thermal oil heaters. Based on such many years experience for manufacturing boilers, Our engineers collected more questions from kinds of our valved domestic and oversea clients, and they improve our boilers day by day. So now Our boilers and accessories can suitable all kind of industrial boilers. Our boiler manufacturer have own ISO9001 qualification system. What′s more, tehy also got SGS certificate, and CE certificate, even ASME certificate. Our boiler lifespan can reach 20 years. We are dedicated to global market. Nowadays, we have exported boilers to more than twenty countries, such as Europe, Middle East, Southeast Asia, and Africa. During the past years, our company is developing quickly and stably at the annual growth speed of 100%. We adhere to the management principles of quot&quality first, customer first and credit-based” Since the establishment of the company and always do our best to satisfy potential needs of our customers.

Qingdao Hammer Industries Co., Ltd is sincerely willing to cooperate with enterprises from all over the world in order to realize a win-win situation since the trend of economic globalization has developed with an irresistible force.

| International Commercial Terms(Incoterms): | FOB, CFR, CIF, DAT, FAS, DDP, DAP, CIP, CPT, FCA, EXW |

|---|---|

| Terms of Payment: | LC, T/T, D/P, PayPal, Western Union, Small-amount payment, Money Gram |

| Average Lead Time: | Peak Season Lead Time: 1-3 months, Off Season Lead Time: one month |

| Number of Foreign Trading Staff: | 1~3 People |

| Export Year: | 2018-08-01 |

| Export Percentage: | 41%~50% |

| Main Markets: | South America, Eastern Europe, Southeast Asia, Africa, Mid East |

| Nearest Port: | QINGDAO |

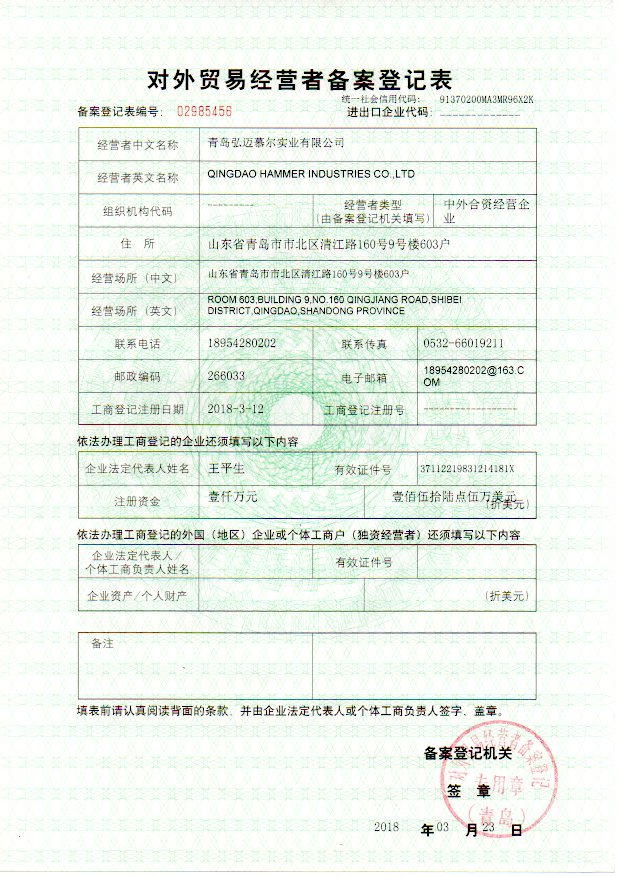

| Import & Export Mode: | Have Own Export License

Export License Number: 02985456 Export Company Name: QINGDAO HAMMER INDUSTRIES CO.,LTD |

| Factory Address: | LIAO LAN TOWN ,PINGDU,QINGDAO ,CHINA |

|---|---|

| R&D Capacity: | OEM, ODM, Own Brand() |

| No. of R&D Staff: | 5-10 People |

| No. of Production Lines: | 2 |

| Annual Output Value: | US$2.5 Million – US$5 Million |

| Ever Annual Output of Main Products: | Product Name Units Produced (Previous Year)

boiler 150 Pieces |