| Certification: | ISO |

|---|---|

| Installation Method: |

Vertical |

| Operation Type: |

Automatic |

Desulfurization Equipment for Boiler Project, Find Details and Price about Boiler Parts Boiler Accessories from Desulfurization Equipment for Boiler Project

| Certification: | ISO |

|---|---|

| Installation Method: |

Vertical |

| Operation Type: |

Automatic |

Desulfurization Equipment for Boiler Project, Find Details and Price about Boiler Parts Boiler Accessories from Desulfurization Equipment for Boiler Project

1. The characteristics of the equipment

Combined the characteristics of the water film dust remover, low cost, convenient installation, corrosion resistance, abrasion resistance, durability, high and stable performance collection coefficient, strong adaptability, can be used for a variety of industrial boiler dust removal and desulfurization and dust places, stable operation, simple maintenance. Support the ideal boiler accessories.

1.1. Using natural granite, after machining into circular plate, the overall structure of the smooth level off. Corrosion resistance, wear resistance, high temperature resistant characteristics.

1.2. Each section 1 meter by using ontology, outsourcing steel plate, with each section excuse concave and convex shape juncture, when installation using acid-resistant rubber coated in seam connection, to ensure that the joint is not leaking.

1.3. Import and export are provided with flange and flange size, installation flange joint with asbestos rope caulking, beware of air leakage, influence dedusting effect.

2. The performance and parameters

Dust removal efficiency: > 98%

The desulfurization efficiency: > 80%

Import smoke speed: 16-20 m/s

Mmh2o cylinder resistance: 70-70

Drops of precipitator cylinder rising smoke speed: 3.5 to 5.5 m/s

The overflow groove static pressure: 2-5 mmh2o

Dust removal after the flue gas temperature: 50-80 ºC

Dust emission concentration < 200 mg/m after

SO2 emission concentration < 800 mg/m after

Salinger, blackness < 1 level

3. The installation

3.1. Composite water film dust remover should be designed according to choose type and installation site geology dust catcher foundation, foundation must level off, the error is less than 5 mm.

3.2. Filter water supply system, air ducts, sedimentation tank and other ancillary facilities must be designed at the time of installation as a whole.

3.3. The overflow tank parts is the key parts, must be installed correctly. Irrigation water level elevation difference after leveling should < 2 mm.

4. Operation maintenance

4.1. Should add fresh water in the pool before operation, and water supply to the filter to the overflow mouth water overflow, check whether the quality is conform to the requirements, smooth water supply system and supply of mouth water not leak tight.

4.2. Before operation, should be induced draft fan, and water supply to the water supply system, the furnace, should stop to supply water to the water system before closing induced draft fan. , in the operation of the cylinder is absolutely not allowed without water, regularly check the overflow tank was clear, want to often observed smoke temperature and flue gas resistance at the same time.

4.3. Regular cleaning are deposited in the sedimentation tank, try to keep the purity of the circulating water.

4.4. For the desulfurization efficiency is above 80%, must be quantitative add lye in circulating cistern regularly, keep circulating water PH value of the above 9, containing acidic waste water in the tank and the alkaline neutralization precipitation can be recycled after filtration.

4.5. Stop for a long time, such as filter operation or runtime upper trough appear flashing phenomenon, should be to provide clean water to sink, such as tap water scour for an hour or so, in order to remove dust in the sink.

5. The pump selection

Suggested use: abrasion resistant submerged pump

| Model | XF-1 | XF-2 | XF-4 | XF-6 | XF-8 | XF-10 | XF-15 | XF-20 | XF-25 | XF-35 |

| Suitalbe for boiler | 1T | 2T | 4T | 6T | 8T | 10T | 15T | 20T | 25T | 35T |

| Out Diameter (mm) | 840 | 1040 | 1240 | 1440 | 1640 | 1900 | 2200 | 2300 | 2600 | 3200 |

| Inner Diameter (mm) | 600 | 800 | 1000 | 1200 | 1400 | 1600 | 1900 | 2000 | 2300 | 2800 |

| Height (mm) | 5500 | 5700 | 5700 | 6800 | 8260 | 10280 | 11500 | 12000 | 13000 | 15500 |

| Desurful smoke capacity (m3/h) | 3000 | 6000 | 12000 | 18000 | 24000 | 30000 | 45000 | 60000 | 75000 | 105000 |

| Weight(kg) | 5000 | 6000 | 7000 | 9000 | 16000 | 21000 | 23000 | 31000 | 42000 | 55000 |

| Anti-corrosion pump motor | 2.2kw | 2.2kw | 2.2kw | 3kw | 3kw | 3kw | 5.5kw | 5.5kw | 7kw | 9kw |

| Business Type: | Manufacturer/Factory, Trading Company | |

| Main Products: | Steam Boiler , Boiler , Coal/Biomass/Oil/Gas Fired Boilers | |

| Registered Capital: | 10000000 RMB | |

| Plant Area: | >2000 square meters | |

| Management System Certification: | ISO 9001, ISO 9000, ISO 20000, QC 080000, GMP, BSCI, BRC, ANSI/ESD, GAP,QSR | |

| Average Lead Time: | Peak Season Lead Time: 1-3 months Off Season Lead Time: one month |

Qingdao Hammer Industries Co., Ltd is engaged in manufacturing and exporting industrial boiler for more than 20years. Such as coal/biomass/oil/gas steam boilers, hot water boilers and thermal oil heaters. Based on such many years experience for manufacturing boilers, Our engineers collected more questions from kinds of our valved domestic and oversea clients, and they improve our boilers day by day. So now Our boilers and accessories can suitable all kind of industrial boilers. Our boiler manufacturer have own ISO9001 qualification system. What′s more, tehy also got SGS certificate, and CE certificate, even ASME certificate. Our boiler lifespan can reach 20 years. We are dedicated to global market. Nowadays, we have exported boilers to more than twenty countries, such as Europe, Middle East, Southeast Asia, and Africa. During the past years, our company is developing quickly and stably at the annual growth speed of 100%. We adhere to the management principles of quot&quality first, customer first and credit-based” Since the establishment of the company and always do our best to satisfy potential needs of our customers.

Qingdao Hammer Industries Co., Ltd is sincerely willing to cooperate with enterprises from all over the world in order to realize a win-win situation since the trend of economic globalization has developed with an irresistible force.

Qingdao Hammer Industries Co., Ltd is engaged in manufacturing and exporting industrial boiler for more than 20years. Such as coal/biomass/oil/gas steam boilers, hot water boilers and thermal oil heaters. Based on such many years experience for manufacturing boilers, Our engineers collected more questions from kinds of our valved domestic and oversea clients, and they improve our boilers day by day. So now Our boilers and accessories can suitable all kind of industrial boilers. Our boiler manufacturer have own ISO9001 qualification system. What′s more, tehy also got SGS certificate, and CE certificate, even ASME certificate. Our boiler lifespan can reach 20 years. We are dedicated to global market. Nowadays, we have exported boilers to more than twenty countries, such as Europe, Middle East, Southeast Asia, and Africa. During the past years, our company is developing quickly and stably at the annual growth speed of 100%. We adhere to the management principles of quot&quality first, customer first and credit-based” Since the establishment of the company and always do our best to satisfy potential needs of our customers.

Qingdao Hammer Industries Co., Ltd is sincerely willing to cooperate with enterprises from all over the world in order to realize a win-win situation since the trend of economic globalization has developed with an irresistible force.

| International Commercial Terms(Incoterms): | FOB, CFR, CIF, DAT, FAS, DDP, DAP, CIP, CPT, FCA, EXW |

|---|---|

| Terms of Payment: | LC, T/T, D/P, PayPal, Western Union, Small-amount payment, Money Gram |

| Average Lead Time: | Peak Season Lead Time: 1-3 months, Off Season Lead Time: one month |

| Number of Foreign Trading Staff: | 1~3 People |

| Export Year: | 2018-08-01 |

| Export Percentage: | 41%~50% |

| Main Markets: | South America, Eastern Europe, Southeast Asia, Africa, Mid East |

| Nearest Port: | QINGDAO |

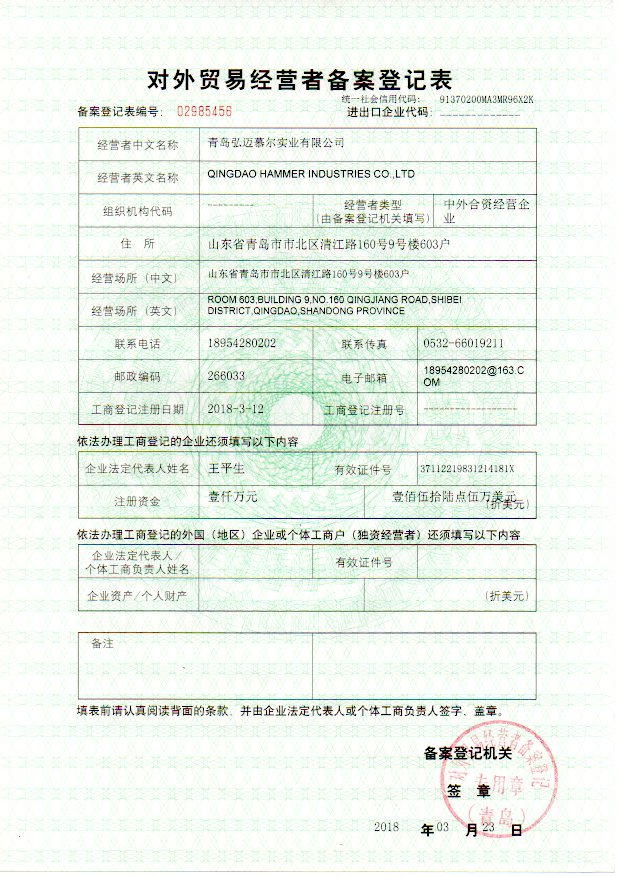

| Import & Export Mode: | Have Own Export License

Export License Number: 02985456 Export Company Name: QINGDAO HAMMER INDUSTRIES CO.,LTD |

| Factory Address: | LIAO LAN TOWN ,PINGDU,QINGDAO ,CHINA |

|---|---|

| R&D Capacity: | OEM, ODM, Own Brand() |

| No. of R&D Staff: | 5-10 People |

| No. of Production Lines: | 2 |

| Annual Output Value: | US$2.5 Million – US$5 Million |

| Ever Annual Output of Main Products: | Product Name Units Produced (Previous Year)

boiler 150 Pieces |